In a significant breakthrough to tackle the freshwater scarcity in various parts of the world, scientists from Indian Institute of Technology Bombay have developed a new material that can facilitate water desalination.

Researchers Professor Swatantra Pratap Singh and Aiswarya C. L. have developed Dual-Sided Superhydrophobic Laser-Induced Graphene (DSLIG) evaporator that addresses multiple shortcomings of earlier evaporators and has the potential for large-scale applications.

While water is abundant on Earth, only about 3% of it is freshwater, and even within that, less than 0.05% is easily accessible. Removing salt (desalination) from seawater and brackish water is seen as one of the solutions to address this problem, with researchers working towards developing more efficient and faster desalination techniques. However, brine (concentrated salt solution) from desalination is a big problem in landlocked places, and industries are looking for zero liquid discharge.

The researchers said that solar energy-based desalination methods are considered desirable due to their reduced carbon footprint. However, factors such as fluctuations in intensity and availability of sunlight and reduced rates of absorption of light greatly affect the efficiency and consistency of solar energy-based desalination techniques.

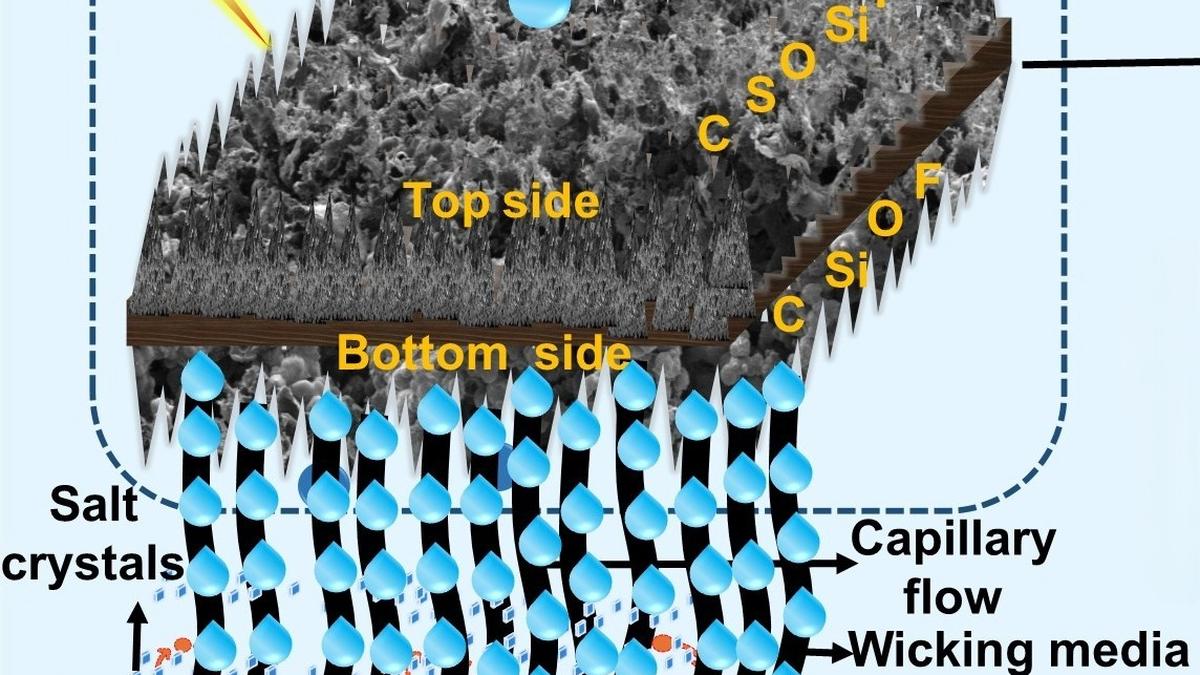

Mr. Singh explained that in recent years, interfacial evaporation systems have emerged as a promising approach. The key component of these systems is an evaporator made from materials that can absorb solar energy and heat up. The evaporator, placed on the surface of the water, focuses solar heat on a thin layer of water at the evaporator’s surface rather than heating the entire volume. This localized heating minimizes heat loss and enhances the efficiency of the desalination process.

However, despite this advantage, the problems with traditional solar desalination techniques do affect interfacial evaporators as well.

“Fluctuations in solar radiation cause temperature variations on the evaporator’s surface. On cloudy days, the performance of the interfacial system is halted due to the lack of solar energy. Additionally, the variation in solar radiation during the day affects the evaporation process, with evaporation rates typically peaking around 2 pm when solar intensity is highest,” Mr. Singh said.

Another major challenge with interfacial evaporation systems is the deposition of salt crystals on the surface of the evaporators. Salt deposition on the surface prevents water from coming in contact with the evaporator, and consequently, its efficiency diminishes over time. This research aims to address both of these issues. In addition to solar heating, DSLIG evaporators can also be heated using electricity (known as Joule heating), Mr. Singh said.

By combining solar and electric heating, the material is protected from fluctuations in the availability of sunlight. When there is less or no sunlight, electricity can be used to heat the evaporator and maintain similar temperatures, ensuring consistent performance. Additionally, DSLIG has a superhydrophobic property, meaning it repels water like lotus leaves.

Owing to the characteristics of their surfaces, superhydrophobic materials reduce the contact area between water droplets and the material surface, making droplets roll over them instead of wetting.

“In desalination applications, the superhydrophobic nature of DSLIG helps prevent salt dissolved in water from sticking to the evaporator surface, thus maintaining efficiency over time. The primary goal of our work was to create a superhydrophobic surface, exhibiting the lotus effect, capable of functioning with both solar and Joule heating,” Mr. Singh explained.

The researchers fabricated DSLIG by coating a layer of a polymer called polyvinylidene fluoride (PVDF) on one side of a thin layer of another polymer LIG, poly (ether sulfone) (PES). Graphene was then engraved on the PVDF polymer side of the material using laser-based engraving technology. “The material derives its name from the fact that it has two distinct sides formed by the two polymers and the fabrication technique used. PES doesn’t repel water, but it is essential to prevent the evaporator from breaking easily. If only PES were used, the final surface would get wet on both sides. However, using PVDF resulted in hydrophobicity on both surfaces. The use of PES as a substrate ensured mechanical stability, while the PVDF layer contributed to the hydrophobic characteristics necessary for efficient evaporation processes,” the professor said.

Laboratory tests show that DSLIG not only exhibits lotus leaf-like behavior, preventing salt deposition and excellent efficiency for desalination under both electric and solar heating, but is also very effective in treating extremely concentrated salt solutions. This makes it an ideal candidate for treating salt water discharges from other desalination outlets as well as industrial wastewater.

The researchers have also demonstrated that the performance of DSLIG improves when multiple evaporators are stacked on top of each other. While the low carbon footprint, low toxicity, and cost-effectiveness make DSLIG a potential candidate for large-scale sustainable desalination applications and the treatment of industrial wastewater. Mr. Singh said that further field testing is required before such large-scale applications can be made.

“One of the major hurdles the team faces in ensuring and testing the industrial readiness of this technology is a lack of funding. In the meantime, we are looking forward to developing more such superhydrophobic materials that can simultaneously utilise both solar and electric energy with even greater efficiency,” Mr. Singh added.

Published – April 17, 2025 07:49 am IST